Precision Agriculture Gives Farmers More Control Over The Field

Instant data collection and dissemination means farmers can predict with accuracy the health and yield of their soils and crops. This is where precision agriculture comes in.

What Is Precision Agriculture?

Advances in technology have enabled agricultural businesses of all sizes to implement precision agriculture. It’s history began through early GPS-satellite adoption, which allowed farmers to gather data and steer agriculture equipment automatically.

This technology has further advanced over time, allowing farmers to gather even more precise data — sensors, aerial devices, stationary IoT solutions for precision agriculture, etc. Now farmers can accurately:

- Harvest historical data, predictive modeling, and environmental insights to select crops with higher yields

- Capture real-time data on site performance

- Achieve sustainable economic and environmental practices on the farm

- Provide the right amount of water, nutrition, and pest control based on digital farming data

- Predict and react to changes in the weather

This is ideal across these disciplines:

| Crops | Grains | Soil | Viticulture |

| With proper analysis, producers are able to accurately measure crop growth, monitor on-farm trials and identify uneven spreading or inconsistent sprays. On the basis of reliable results, farm management and planning decisions are much easier. | As the grain production industry increasingly uses precision ag monitoring solutions, farmers can use NIR and hyperspectral solutions to answer key questions about crop rotation patterns, yield management, storage and irrigation. | Sustainable farming starts with the soil as the base, using analysis to develop a long-term program. Reliable, reproducible analysis of soil texture, soil moisture, salt levels and paddock rotation is achievable through hyperspectral analysis. | Satellite and airborne platforms provide images depicting vineyard conditions, maximising grape yield and quality while managing location-specific risks and variations. Achieves the best results and optimises harvests in this lucrative industry. |

Advantages Of Precision Farming In Agriculture

Technology is seen as a way by agriculture business owners to improve the quality of decision-making, the ROI, as well as the overall security of their facilities.

More Monitoring Data

Growers can continuously monitor a wide range of metrics thanks to digital tools. They will keep track of rainfall levels, the sources and types of nutrients their crops need, soil samples, fertiliser inputs, etc.

Improved Efficiency

In the long run, farmers gain valuable real-time access to valuable real-time data when they adopt precision agriculture sensors to monitor soil moisture, crop health, and nutrition levels. By recognising patterns and forecasting changes, potential risks, and yields, a site manager can maximise efficiency and profitability, during both harvest and planting season.

Increased Crop Protection

Overuse of chemicals is one of the reasons for high crop and soil pressures. In an effort to prevent crop damage from insects, farmers often overuse nitrogen. The use of chemicals reduces the sustainability of the site – and it’s costly. Precision ag helps farmers optimise pest control and use chemicals only when needed and protect crops more efficiently.

Irrigation management

With precision ag, a farming team can accurately tell when to irrigate a field using centralised command-and-control tools.

Incorporating Spectroscopy Into Precision Agriculture

The use of spectroscopy allows for precise crop/food analysis and quality control.

And using spectroscopies in small portable devices, such as portable drones and handheld devices, has only further increased the application of these techniques.

Crop and food analysis by conventional methods is time-consuming, complex, destructive, and requires infrastructure and resources. Simple or no sample preparation is often required for spectroscopy measurements, and it’s easy for farmers to use and interpret the data.

How Spectroscopy Works

Spectroscopy is widely used as an analytical tool in many different fields due to its precise and non-destructive nature.

In spectroscopy, the wavelength of light and other materials are used to measure the absorption, transmission, and emission of electromagnetic radiation. Spectroscopy also includes the calculation of collision energies between electrons, protons, and ions within a compound and those of other compounds.

Foods and crops are analysed and quality controlled using spectroscopy in agriculture. Chemical composition, microbial infections, toxins, pests, pathogens, and adulteration are some of the uses. Defects also can be monitored both internally and externally.

Optical Spectroscopy in Agriculture

Agricultural use of optical/light spectroscopy is common.

Each element or compound has its own spectral signature based on its composition and will respond to different wavelengths. For this reason, spectroscopy is used in biological sciences to determine the composition of materials as well as to conduct quantitative analyses.

Spectra of light are made of varying wavelengths, frequencies, and energies.

Agriculture draws heavily on spectroscopy’s use of the infrared (IR) and ultraviolet-visible spectral ranges.

Ultraviolet-visible (UV-VIS)

The ultraviolet-visible spectrum used for spectroscopy lies within the UV (100 nm to 380 nm) and visible (380 nm to 750 nm) range of wavelengths.

UV-VIS spectroscopy is primarily used to control the quality of edible oils. Two aspects of oil that can be tested are: fat oxidation and the overall colour.

- Fat oxidation:

A measure of fat oxidation is the anisidine value (AV). When exposed to light, oxygen, and high temperatures, fat is oxidised. The amount of aldehyde produced is measured by AV. An oil’s AV should not be greater than 8 to prevent oxidation, which reduces its quality.

- Oil colour:

In cold-pressed oils, plant pigments such as chlorophyll or carotenoids can colour the oil. Due to the removal of pigments during refining, refined oils have very little pigment. Food producers strive to increase the amount of carotenoids in food oils, since they are healthy antioxidants. On the other hand, chlorophyll promotes oxidation and gives oil a bitter note, so keeping chlorophyll concentrations low is necessary to keep consumers happy.

Fluorescence Spectroscopy

It is a phenomenon in which a fluorescent molecule or fluorophore emits light after absorbing UV light and visible light.

Quantitative analyses are frequently carried out using fluorescence spectroscopy, which is sensitive and specific enough to detect low levels of compounds. This makes fluorescence spectroscopy ideal for handling contaminants and for structural analysis. Several techniques can be used with fluorescence, including liquid chromatography and fluorometry.

- Control of toxins

Salmonella, mycotoxins, and other pathogenic microbes or fungi can produce toxins as contaminants in food. A toxin may also be present in food when it is an antibiotic (penicillin) or an additive (aspartame).

- Structural analysis

Proteins, carbohydrates, and lipids in oils can be detected by fluorescence. Oils can be checked for adulteration with cheaper substitutes with this property. In oil that has been repeatedly fried, fluorescence can determine vitamin E, anisidine, and iodine levels.

Near-Infrared Spectroscopy

Near-infrared is the most widely-used technique in spectroscopic applications for agriculture and is applied for quantitative analysis.

A Spectrometer For Every Occasion

The ASD FieldSpec 4 leaves the factory floor calibrated as a spectroradiometer, ready for precise radiance and irradiance measurements, but is equally suited for use as a spectrometer for accurate contact or stand-off reflectance analysis with a wide range of standard accessories.

All ASD FieldSpec spectrometers and spectroradiometers provide 3 nm spectral resolution in the VNIR (350 nm – 1000 nm) range. Four spectral resolution options are available for the SWIR (1001 nm – 2500 nm) range.

- The enhanced 6 nm SWIR spectral resolution of the ASD FieldSpec 4 Hi-Res NG spectroradiometer provides both the sampling interval (bandwidth) and the spectral resolution to support accurate calibration and image classification analysis with the next generation high spectral resolution hyperspectral sensors.

- With 8 nm SWIR spectral resolution the ASD FieldSpec 4 Hi-Res spectroradiometer is the instrument of choice for geological studies and atmospheric research.

- The ASD FieldSpec 4 Standard-Res spectroradiometer, with 10 nm SWIR resolution is perfectly suited for characterizing spectral features with a resolution of 10 nm to 50 nm, which covers the technical requirements of most field researchers. The ASD FieldSpec 4 Standard-Res spectroradiometer has long been the industry’s go-to workhorse instrument for trusted field spectroscopy and the scope of potential applications is broad.

- Because of its wide optical slit the ASD FieldSpec 4 Wide–Res spectroradiometer provides the highest signal throughput and offers the best signal to noise performance of any ASD FieldSpec model. These high throughput characteristics also benefit field measurements taken in less than optimal illumination conditions.

- The 30 nm SWIR resolution of the ASD FieldSpec 4 Wide-Res spectroradiometer makes it an ideal fit for applications such as vegetation analysis and vegetation indices that are characterized by broad spectral features. This instrument is also available at a significantly lower price point than other ASD FieldSpec models, which makes it an attractive option when budgets are tight.

The Gold Standard In Field Spectroradiometers

ASD FieldSpec® line of full-range spectroradiometers deliver the fastest and most accurate spectral field measurements available with excellent performance, signal and integration speeds.

The FieldSpec range has been designed around the specific needs of researchers when collecting spectral measurements in the field. Long-range wireless increases collection coverage potential from a stationary base. Superior signal throughput, signal-to-noise, and radiometric performance regardless of atmospheric conditions.

All ASD FieldSpec spectrometers and spectroradiometers provide 3 nm spectral resolution in the VNIR (350 nm – 1000 nm) range. Four spectral resolution options are available for the SWIR (1001 nm – 2500 nm) range – Hi-Res NG, Hi-Res, Std-Res, Wide-Res. Full range (350 – 2500 nm)

- Comprehensive options for UV/Vis/NIR/SWIR field requirements

- Faster integration speed facilitates more measurements in a limited solar collection time window

- Permanent fibre-optic cable design reduces the risk of signal loss

- Pro-pack backpack easily allows field portability with the FieldSpec 4 product line

LabSpec NIR SpectrometersAnalytical Spectral Devices (ASD) – NIR

Portable, laboratory-grade instrumentation for fast-moving environments, LabSpec performs rapid, non-destructive qualitative and quantitative materials analysis using state-of-the-art NIR technology.

With options in Standard-Res, High-Res and Benchtop analysers, these spectrometers are optimised for rapid analysis, providing instant results with no sample preparation.

- Evaluate hundreds of samples per day

- Real-time identification of liquid and solid spectral characteristics

- Measure multiple properties simultaneously

- Compatible with ASD sampling accessories.

Speak to PAS for expert advice on the precision agriculture solution best suited to your application.

There are many categories of NIR spectroscopy use in agriculture:

- Pest, Disease, and Toxin Detection

NIR is used to detect fungal contamination and estimate levels of mycotoxins.

- Drought management

Due to its unique spectrum, water levels are monitored to determine if crops are suffering from water stress and adjust irrigation accordingly.

- Maturity

Dry matter content is used to determine when they are mature enough for harvest. Green mature fruits should be estimated based on dry matter to avoid harvesting them too early and preventing proper ripening. By harvesting them later, transportation and storage time would be reduced.

- Fertiliser application

Leaf spectrometry can be used to track plant growth. Scientists and farmers can monitor crop progress and respond by applying the correct nutrients to the crops.

- Processing

Process centres must determine parameters such as dry matter, BRIX, and water content. It is also possible to use NIR to detect them, choose the best fresh produce, and monitor the production process.

- Post-harvest quality control

The storage, transportation, and retail sale of climacteric fruits can take months after harvest. In order to eliminate spoiled produce and prevent the rest of the product from being affected by ethylene, various quality parameters, such as ripeness, internal damage, and external appearance, can be monitored.

PAS’s Full Range Of Precision Agriculture Solutions

- Highest-quality range of imaging products

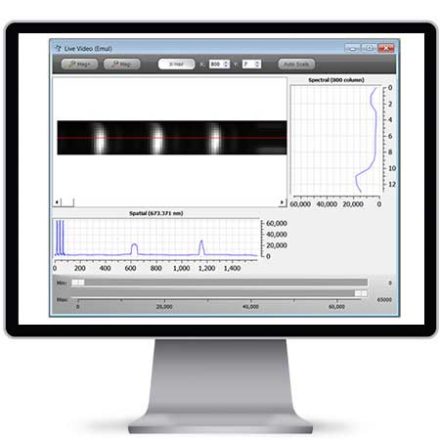

- Featuring custom-designed data collection software

- Lab-based, ground or airborne solutions

For solutions in hyperspectral imaging for precision ag, speak to PAS about its hardware and software offerings from ASD Inc. and Headwall Photonics. Contact us today.