XRF (X-Ray Fluorescence) Explained

Portable Analytical Solutions

XRF (X-ray Fluorescence) is a non-destructive analytical technique used to determine the chemical composition of materials.

XRF (X-Ray Fluorescence) has a broad range of applications across many industries, so to understand if and how it might work within your field, let’s take a closer look at what it is.

Specifically, in this article we will discuss:

- What XRF is

- How it works

- Strengths & limitations of XRF

What is an X-Ray

Quite simply, X-rays are light waves that we cannot see. They have a very short wavelength, which corresponds to a very high energy, meaning they can pass through most objects.

X-Ray Properties:

- Propagated in straight lines at speed of light

- Absorbed while passing through matter, depending on composition and density of the substance

- Emitted with energies characteristic of the elements present

- Affect the electrical properties of liquids and solids

- Cause biological reactions such as cell damage or genetic mutation

- Darken photographic plates

- Ionize gases

What is X-Ray Fluorescence (XRF)?

XRF occurs when a fluorescent (or secondary) x-ray is emitted from a sample that is being excited by a primary x-ray source. XRF is an excellent technology for qualitative and quantitative analysis of material composition, because the fluorescence is unique to the elemental composition of the sample – hence why it is so versatile and has a wide range of applications.

The X-Ray Fluorescence Process

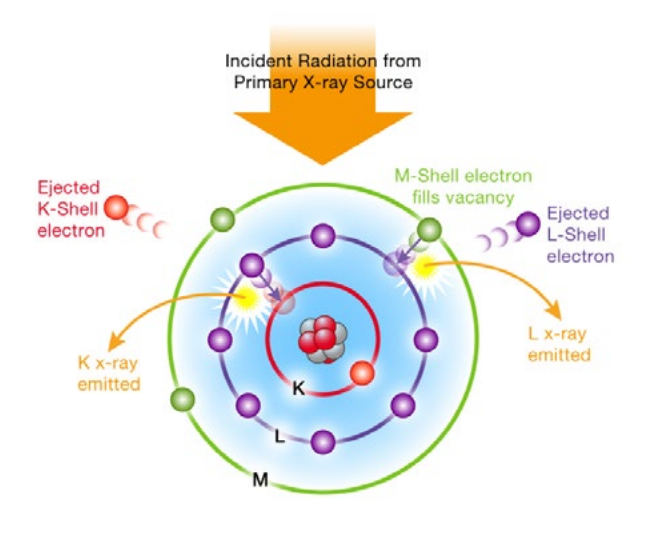

A solid or liquid sample is irradiated with high energy x-rays from a controlled x-ray tube.

When an atom in the sample is struck with an x-ray of sufficient energy (greater than the atom’s K or L shell binding energy), an electron from one of the atom’s inner orbital shells is dislodged.

The atom regains stability, filling the vacancy left in the inner orbital shell with an electron from one of the atom’s higher energy orbital shells.

The electron drops to the lower energy state by releasing a fluorescent x-ray. The energy of this x-ray is equal to the specific difference in energy between two quantum states of the electron. The measurement of this energy is the basis of XRF analysis.

What are Portable XRF (PXRF) Analysers?

Handheld and portable XRF analysers provide instant analysis in any field environment, thanks to their lightweight design and ease of use. They are routinely used for rapid quality control inspection and analysis to ensure product chemistry specifications are met, and have become the standard for non-destructive elemental analysis in a wide range of applications.

Now on their seventh generation, portable XRF technology has become increasingly sophisticated, with new capabilities including smaller size, increased speed, better performance and greater ease of use.

Today’s portable XRF analysers are miniaturised and designed for ultra high speed with lab-quality performance.

How PXRF Analysers Detect X-Rays

The detector is an important part of all XRF instrumentation, since it is responsible for determining the elements present in a given sample by accurately and nondestructively “reading” the fluorescent x-rays.

When the characteristic x-rays enter the detector, their electromagnetic energies are converted to electrical pulses. These pulses are then sorted into element channels in a Digital Signal Processor (DSP).

Next, the “counts” from each element are sent to the microprocessor, which contains the algorithms for calculating the concentration of each element from the count rate data.

There are two main types of detectors in handheld XRF technology:

Silicon Drift Detectors (SDDs)

SDDs are high-resolution detectors that can be used in high count-rate applications. The larger the active area of the detector, the more efficiently it can gather and process x-ray counts.

XRF instrumentation employing SDD can be used in applications that require extreme sensitivity, such as the detection of tramp elements that can degrade the performance of alloys.

Residual elements can be measured with a confidence once only possible in the lab. SDD’s are also required to analyse light elements such as Magnesium (Mg), Aluminium (Al), Silicon (Si), Phosphorus (P) and Sulfur (S).

The introduction of SDDs into PXRF instruments has produced significant performance improvements over traditional XRF capabilities.

PIN Detectors

This is a high-performance, high-resolution technology conventionally used in handheld and portable XRF instrumentation. It is appropriate for numerous industry applications.

PIN Detectors measure the fluorescence radiation emitted from the sample after it has been irradiated, usually by an x-ray tube (occasionally by a radioactive source).

Instruments with Silicon PIN detectors are sensitive to X-rays that are higher on the periodic table than Sulfur (S) and tend to be less expensive than instruments with Silicon Drift Detectors.

Limitations of Handheld XRF

The fluorescent x-rays from lighter elements (Z<18) are less energetic and are greatly attenuated as the x-rays pass through air, meaning analysis of these elements with handheld XRF can be challenging.

Spectral Effects

Some elements have lines that overlap other elements, which can make detection challenging – especially when two overlapping elements are present.

Fortunately the software will strip out and correct most of these overlaps (as long as the interfering element is in the mode being used).

Matrix Effects

The matrix refers to any other element present in the sample, other than the one element being considered.

If however you are using a fundamental parameters based calibration with all the necessary elements present, enhancement and absorption effects are typically taken care of in the software.

Enhancement Effects

Some fluorescent x-rays have more energy than the binding energy of other elements present in the sample, so their energy will excite those other elements. These elements will give a greater signal return to the detector, therefore “enhancing” the reading.

Absorption Effects

If the fluorescent x-ray is scattered or absorbed by other elements present in the sample, it will not reach the detector so the signal is weaker.

Sample Effects

XRF is a surface analysis technique, so if the surface of the material being analysed is not representative of the entire sample (particle size, inhomogeneity, surface contamination etc) the results will be skewed.

Strengths of Portable Handheld XRF Analysers

- Lightweight

- Easy to use

- Cost-effective

- Nondestructive

- Accurate results

- Instant results

- Portable

- Used onsite

If you’d like to discuss your PXRF requirements, please get in touch and chat with one of our experts.