Safety, Quality, and Consistency: How Machine Vision Applications are Transforming the Food Industry

Every business has to maintain certain standards, but few have more stringent requirements than food industry operators.

Any quality issues they experience can have extremely serious consequences, legally, financially and to their reputation. This means they have almost no margin for error.

This means careful monitoring and robust controls must be built into every step of their production processes.

While these have traditionally been manual interventions, food industry operators are increasingly turning to technology to manage quality assurance. In particular, machine vision applications have grown significantly over recent years to cover most elements of food production.

Here we take a closer look at what machine vision is and its many different applications in the food industry.

What is Machine Vision?

As the name suggests, machine vision allows industrial equipment to see what it is doing.

It is a broad term for a range of technologies that analyse visual inputs and respond based on their analysis. A foundation of industrial automation, it was first introduced in the 1970s and has helped significantly improve the speed and quality of production processes.

Machine Vision and the Food Industry

Several factors are driving steady growth in machine vision applications within the food industry.

Most significantly, in Australia operators need to meet strict standards regarding the production, handling, processing, and packaging of food. Failing to meet these standards can result in substantial fines, licensing issues, and even criminal convictions.

Food safety incidents can also have a big impact on a business’s reputation, with many businesses being forced to close after a major quality issue.

Profit margins within the food industry are also quite volatile and generally very tight. As such, operations need to be designed to be as efficient as possible, without putting quality at risk.

This is where technology, and particularly machine vision, can help. It provides a cost-effective way to monitor the quality of all produce and packaging, and ensure consistent standards are maintained. When compared to manual monitoring, it is also much more reliable and can operate at significantly faster speeds.

What’s more, as machine vision technology has developed, it has become capable of far more complex analysis and hazard identification. As a result, it can now detect minute defects and contaminants that are not visible to the human eye.

It can also do this without damaging, or even touching, the produce, which helps maximise yields and reduce wastage.

Common Applications of Machine Vision

Maintaining the quality and consistency of food products requires careful monitoring and management of every step of the production process. Machine vision technology can support this, with different functionality adapted to suit a range of different applications.

Harvesting and Sorting

Hyperspectral imaging can be used to detect diseases in plants and measure the key indicators of ripeness in a range of different crops. Machine vision can also enable harvesting equipment to better locate produce (e.g. grapes and other berries) and pick it without damaging it. This can help increase the quality of produce while also reducing wastage.

Once a crop has been harvested, machine vision can also be used to sort the produce into different grades. It can quickly assess the colour, shape, and size of individual items against predetermined minimum standards.

It can also identify imperfections and blemishes, and assess other important quality measures like water and sugar content, pH level, and macronutrient profile.

Identifying Foreign Objects

Even with the tightest quality controls in place, there is still a risk of unwanted material infiltrating produce and packaging.

Machine vision can help identify when this has happened, allowing the foreign objects to be removed before further processing. It can also help identify cross-contamination, which is particularly important for facilities that handle common allergens, like nuts.

Spectral imaging can also be used to identify contamination that is not visible to the human eye. For example, it can identify the early signs of mould development and measure the levels of harmful bacteria, like salmonella and E. coli. Best of all, as it is a non-destructive form of testing, it can do this without damaging the produce.

Inspecting Packaging

Correct packaging is crucial to ensuring that the quality of produce is maintained for as long as possible.

To help with this, machine vision can be used to confirm that all packaging materials are clean and structurally sound. It can also confirm that the correct packaging components have been used and that everything is properly sealed, which also helps prevent wastage.

During the packaging process, machine vision can also be used to improve the accuracy of batching. It can confirm that the number, weight, or volume of produce in each package is consistent. It can also identify packages that have been underfilled, allowing them to be removed or remediated before shipping.

Tracking and Labelling

Within the food industry, and more generally, one of the most widespread applications of machine vision is supporting inventory management. It can be used to monitor the inputs and outputs of the production process, compiling a tracking history of each finished product.

In the event of any serious quality issues, this can help identify the root cause and the scale of its impact.

Machine vision technology can also be used to improve the quality, consistency, and accuracy of product labelling.

It can track key data and ensure that all codes, dates, and product information are correct. It can also identify products that are mislabelled or have damaged or unreadable labels, allowing them to be fixed before shipping.

Choosing the Right Tool for Your Machine Vision Needs

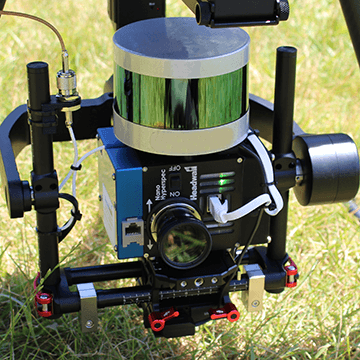

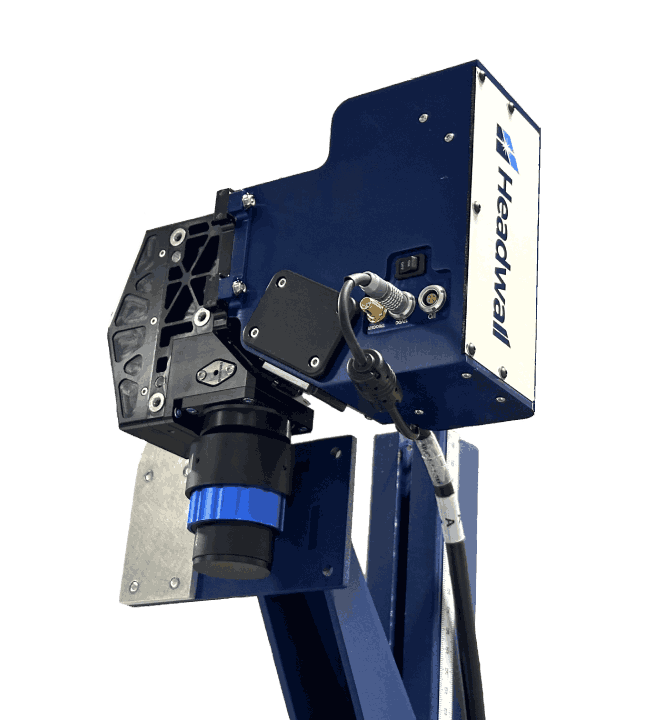

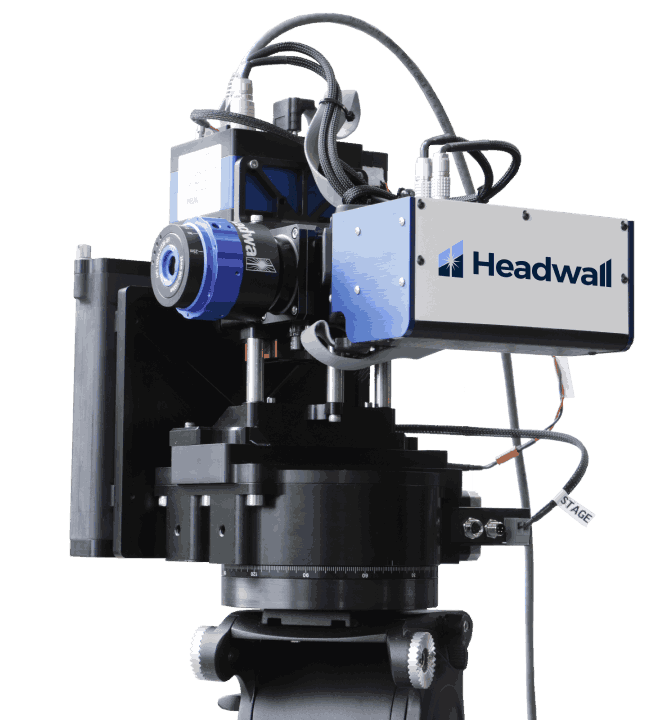

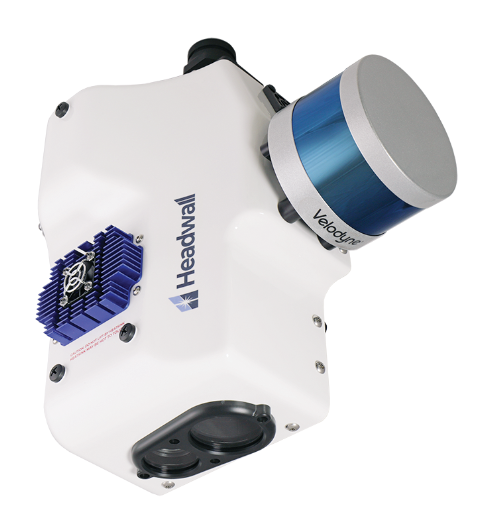

If you’re looking for a fantastic product to help you leverage machine vision technology, the Hyperspec MV.X is sure to impress.

The simple but effective design of this powerful tool makes it the perfect choice for concentric imaging and line-scanning. More than just a camera, its fast, embedded processing enables advanced model development and provides actionable results in real-time.

For more information on potential machine vision applications within the food industry, or to get your own Hyperspec MV.X, contact us today.