For Food Quality And Safety, This Hyperspectral Tool Is A Cut Above

Automated, accurate, and flexible hyperspectral machine vision has revolutionised food manufacturing and inspection processes, such as in the meat and fruit industries.

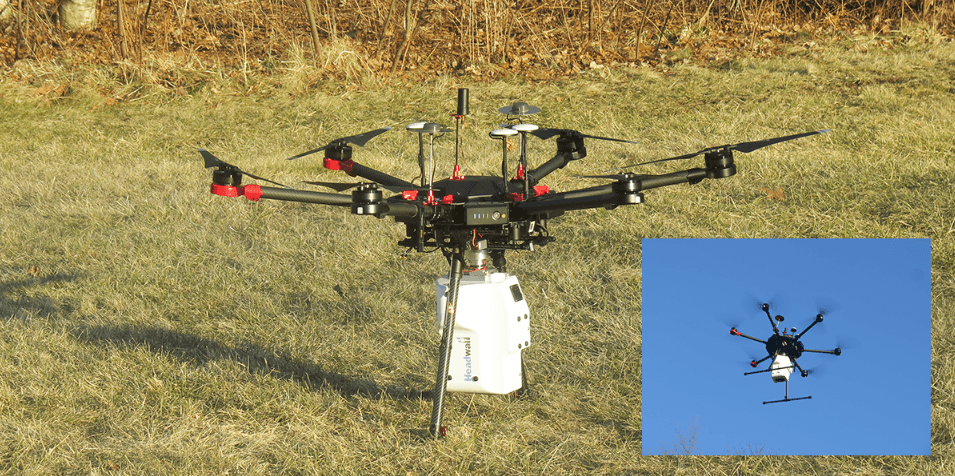

MV.X – Headwall’s award-winning hyperspectral technology – solves and highlights food quality and safety issues using its powerful, embedded computing power and a high-performance VNIR spectrometer to provide real-time, actionable results.

Introducing The Hyperspec® MV.X

|

Hyperspectral imaging is no longer limited to the lab, as Headwall’s MV.X combines high-speed processing power with industry-leading hyperspectral imagery for live classification. Clients, such as food-processing plants, use this to detect potentially harmful foreign materials for removal. You can even use the MV.X offline to create AI detection and grading algorithms which can then be uploaded and stored on units installed on the line and which act on incoming hyperspectral data in real time. Designed for use in harsh industrial environments and capable of functioning both inside and outside, the MV.X offers simplicity of installation and direct output of actionable results. |

How To Apply The Hyperspec® MV.X

| Foreign object detection | Safety and Pathogen detection | Sorting and grading | Process analytics | Contamination detection |

|

Fruits and vegetables such as apples and tomatoes aren’t all the same. They differ in shape, ripeness, optical qualities, weight, and bruising. It is more efficient to market the harvest when these qualities can be precisely measured. It is also important that produce is sorted accurately to prevent inaccurate pricing. |

Detect And Measure With The Hyperspec® MV.X

|

Using hyperspectral imaging to detect foreign matter and pathogens that are invisible to the naked eye can improve the safety of food. This form of imaging provides far better material classification than RGB colour cameras on poultry, seafood, lamb, beef, and specialty crops. A high level of biogenic amines indicates the decomposition of seafood. A rise in histamine levels is typically associated with such decomposition. This is also called “scombroid fish poisoning”. By measuring the concentration of histamines in fish, hyperspectral imaging provides a method for determining the freshness of fish in an instant, contact-free manner. |

Sort And Detect With The Hyperspec® MV.X

|

To meet government regulations, the global food inspection industry needs newer and more precise tools for everything from specialty crops to seafood and poultry. In order to overcome the uncertainties resulting from human inspections or limited capacity RGB cameras, more advanced high-resolution imaging systems are being adopted that are also reliable, affordable, and easy to deploy. Using techniques such as hyperspectral imaging, food producers can sort and detect contamination at the right time, improving product quality and consistency and avoiding costly recalls. A key differentiator for hyperspectral imaging sensors is their ability to classify food based on a number of geometrical and spectral parameters. Rather than simply interpreting “pass” or “fail” measurements, nuts and specialty crops can be inspected in ways that maximise quality and productivity. |

Benefits Of The Hyperspec® MV.X

• Visualise value at the speed of light

• Classify and detect using the spectral dimension

• Hyperspectral classification is intuitive, reliable, and fast

Key Features Of The Hyperspec® MV.X

Specifically designed for advanced machine vision and process analytics applications, the dust-proof and watertight MX.V system is compact, dust-proof, and watertight.

The perClass® MIRA software features machine learning and artificial intelligence to process data runtime and simplify model development.

The MV.X web user interface also allows for remote system control and maintenance.

Suitable for both indoor and outdoor installations, this rugged solution can be installed in any production environment. It includes:

- Hyperspectral Imaging System – not just a camera

- Built for challenging VNIR (400-1000nm) machine-vision apps on the processing line

- Fast onboard, embedded processing for real-time classification

- GenICam-compliant GigE interface with an IP67-rated housing

- Flexible yet robust and straightforward workflow

Technical Specifications

The Hyperspec® MV.X has:

- A spectral range of 400-1000nm

- 270 spectral bands

- 640 spatial pixels

- Max frame rate: as high as 485Hz

- FWHM slit image: 6nm

What is Spectral Imaging?

In spectral imaging, every location in an image plane is sampled for spectral information.

There are several techniques available, based on a variety of factors, including spectral resolution, number of bands, the width, and the presence of adjacent bands.

The process of hyperspectral imaging, like other types of spectral imaging, involves collecting and analysing information that spans the electromagnetic spectrum.

Using hyperspectral imaging, you gain information about each pixel in an image of a scene, in order to locate objects, identify materials, or detect processes.

PAS provides leading Spectral Imaging solutions and support. For more information on Headwall’s Hyperspec® MV.X and how it can help your business, give us a call today.

Related links:

Product data sheet (PDF)

Oregano & Parsley: Quality Inspection of Herbs & Spices (PDF)

The Future Of Food (PDF)

Food Authority (NSW)

Food Standards Australia & New Zealand

Department of Agriculture, Water and the Environment