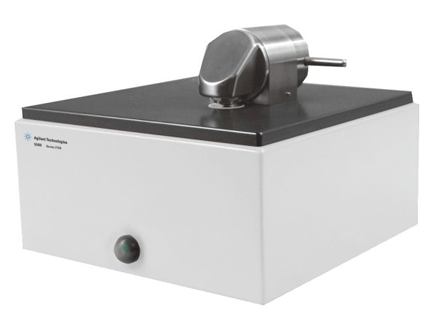

Agilent 5500 Series FTIR™

Agilent Technologies –Fourier Transform Infra-Red (FTIR)

Agilent 45500 Series FTIR

The Agilent 5500 Series Fourier Transform Infrared (FTIR) instruments are advanced mid-infrared region spectrometer platforms that offer the same capabilities as larger and more traditional FTIR spectrometers. However, they are designed to be smaller in size, easier to maintain, and more affordable.

These instruments are specifically designed to provide precise results in material analysis without the complexity, high maintenance requirements, or expensive costs associated with larger FTIR spectrometers. The Agilent 5500 Series FTIR instruments offer accurate and reliable performance, making them an excellent choice for a variety of applications in different industries.

The Agilent 5500 Series FTIR is a powerful tool that features:

- Longer path length capabilities in transmission spectroscopy in a user-friendly format similar to ATR with the 5500 DialPath analysers.

- Quick analysis of samples by placing a single drop of liquid on the surface of the 5500t analyser and rotating a second window into position to sandwich the sample.

- Available with one, three, or five reflection-diamond ATRs, catering to various applications, including single-reflection diamond ATR for solids and liquids identification and multi-reflection ZnSe ATR for liquid analysis.

- Intuitive, method-driven, multi-language software that guides users through every step of the operation, ensuring ease of use. The software features colour-coded alerts to confirm whether samples meet specifications.

- MicroLab Quant provides a simple, guided quantitative methods development package, making it easy to develop and optimise quantitative methods quickly and efficiently.

- Optional MicroLab Pharma supports compliance with data integrity regulations, ensuring accurate and reliable data analysis.

How To Apply The Agilent 5500

Chemical Analysis / Oil Analysis /

Speak to PAS for expert guidance on FTIR analysers such as the Agilent 5500 Series.